- Manufacturing Facility

- Facility

- 90,000 Square Foot Indoor Manufacturing Area

- 12 Acres Total Yard Area and Storage

- Crane Capacity

- 2 @ 20 Ton Overhead Cranes

- 2 @ 40 Ton Overhead Cranes

- 1 @ 35 Ton Yard Crane

- (Able to handle any tonnage necessary)

- Eve Height of Buildings

- 30 ft Pipe and Small Vessel Shop

- 50 ft Main Facility

- Facility Certifications

- U, U2, R, NB

- Materials of Construction

- Carbon Steel

- Stainless Steel

- Clad

- Special Materials

- Welding Procedures

- GMAW, SMAW, GTAW, SAW, & FCAW

- Plate Rolling Capabilities

- 3 ¼” x 10’ & lighter- 120” to Approx. 45” ID in several passes

- 2 ½” x 10’ & lighter to approx. 42” ID in several passes

- Sand Blasting & Painting

- Heated Indoor Paint Booth: 21’ W x 65’ L x 19’ H

- Outdoor Covered Painting Area: 50’W x 50’ L x 50’ H

- Sandblast Building: 50’ W x 50’ L x 50’ H

- Engineering

Our Engineering department has Chemical & Mechanical Engineers utilizing the latest PROMAX design software to insure the highest level in equipment design & operation efficiencies.

Engineered Packages:

- Separation Equipment

- Process heaters

- Oil Treating Systems

- Liquid Recovery

- Production Units

- Sweetening Equipment (H2S, CO2)

- Oil & Gas Dehydration Systems

- Gas Filtration

- Structural Systems

- Piping Systems

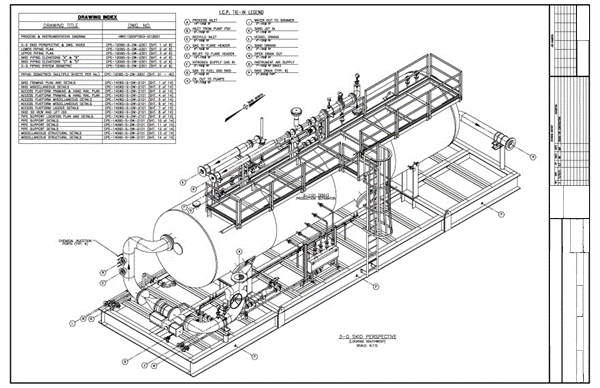

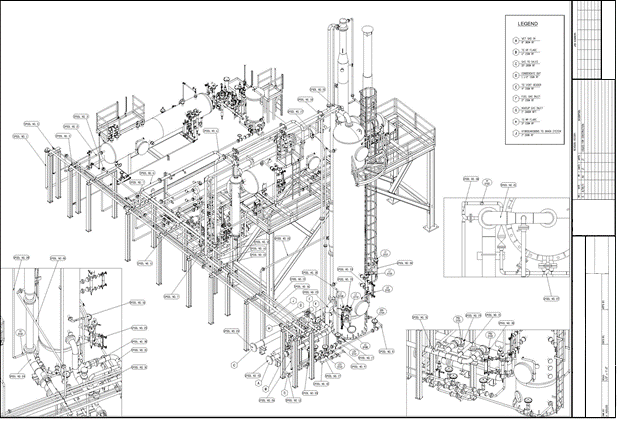

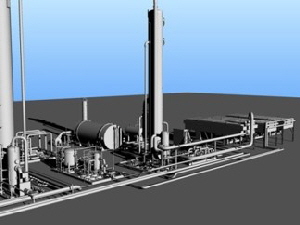

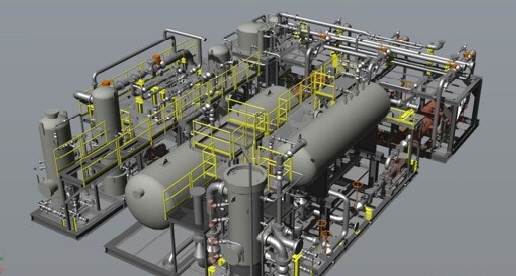

- Modular System Packaging

- 3-D Modeling

Our 3D modeling and ISO PRO design software provides complete in-house project design.

- Separation Products

3-Phase Separators

DRG’s 3-Phase separators are built to ASME Section VIII and NACE MRO-175. These separators can be used in Welltesting and Production applications. Units are designed to be skid mounted or trailer mounted for ease of mobility and transporting for one well site to another. These vessels are manufactured with a Manway, a removable vane pack and an adjustable spillover weir to adjust to a wide range of gas/liquid combinationsSeparator Packages

DRG’s Well Test & Flow Back separator systems have been designed to stand up to the most rigorous well conditions and have been deployed on many US shale sites while meeting all safety and environmental standards set forth by the top OPC’s that utilize our equipment. DRG designs and manufactures all of its equipment in-house and has the expertise to provide solutions to your existing well testing needsSand Separators

DRG’s 5,800 psi sand separators are built to ASME Section VIII and NACE MRO-175. These separators can be used in inline before your Welltesting and Production equipment. Units are mounted on an L-shaped skid mobility and transporting for one well site to another.

Condensate Storage Vessels

DRG’s designs and manufactures condensate storage tanks, commonly known as “Bullet Tanks”. Typical capacity design ranges are:• 18,000 Gal

• 30,000 Gal

• 60,000 Gal

• 90,000 Gal.

Vessel dimensions range from 108” OD x 50’ S/S to 144” ID x 100’ S/S. Pressure ranges in these designs are from 150 psi to 700 psi. All vessels built to ASME Section VIII latest edition.

- Crude Treating

- Stabilization & Dehydration Plants

Condensate Stabilizer Packages

DRG’s Condensate Stabilizer Units provide the most effective way to reduce the vapor pressure in liquid hydrocarbons allowing the product to be stored in atmospheric tanks. CO2 and other non-hydrocarbons can also be removed from the sales product with this process. Our in-house engineering department utilizes the latest technology and engineering practices to properly size the column and reboiler to reduce fuel consumption and installation cost. Packages range from 1,000 BPD to 20,000 BPD.

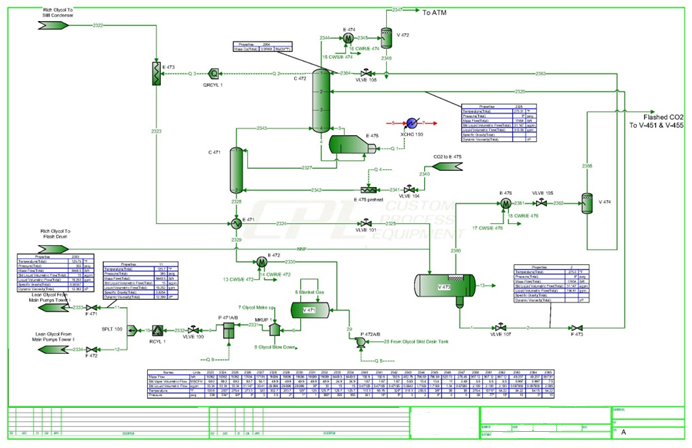

Glycol Dehydration Units

DRG’s designs and manufactures the most commonly used Triethylene Glycol (TEG) units for removing water vapor for the natural gas stream. These units help prevent slugging, hydrate formation and corrosion in pipelines. Unit designs range from the small compact (1) GPM units to the multi-skid (100) GPM Units. Optional stripping gas components can be added to the units to increase the design efficiency as needed per outlet composition requirements.

- Gas Sweetening Plants

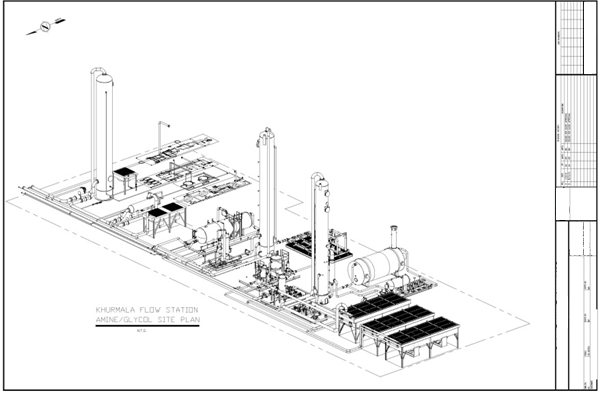

Amine Plants

DRG’s manufactures gas sweeting equipment ranging from 60 GPM to 700 GPM. Plant design is based on onshore or offshore requirements. DRG utilizes PROMAX process design software to insure the highest efficiency in our units and we do provide a process guarantee on all equipment our engineers approve and manufacture.

700 GPM Amine Plant Offshore Compact Model

700 GPM Amine Plant Land Based Model

- Logistics & Freight Forwarding

Sea & Air Freight Forwarding:

Comprehensive sea and air freight services, offering reliable and efficient transportation solutions. Collaboration with major carriers and airlines to ensure timely deliveries. Customized solutions to meet specific customer requirements.

Rail & Road Freight Forwarding:

Integrated rail and road freight services for domestic and international transportation. Efficient and cost-effective solutions for various cargo types. Real-time tracking and monitoring for secure and timely deliveries.

Multimodal Logistics Services:

Seamless integration of multiple transportation modes to optimize logistics. Coordination of sea, air, rail, and road transport for efficient and flexible solutions. End-to-end management for smooth and reliable logistics operations.

Project Cargo Management Services:

Specialized handling of complex and oversized cargo for major projects. Customized logistics planning and execution to meet project-specific requirements. Expertise in managing heavy lift, breakbulk, and out-of-gauge cargo.

Customs Clearance and Documentation Services:

Expert customs brokerage services to ensure smooth clearance of goods. Comprehensive documentation management to comply with international regulations. Minimization of delays and costs through efficient customs processes.

Dealing with Different Airline Options (IATA and Non-IATA):

Wide range of airline options to meet diverse customer needs. IATA and non-IATA airline partnerships for flexible and reliable air freight solutions. Tailored solutions to optimize cost and transit time..

Door to Door Services:

Flexible delivery options to suit customer preferences. Airport-to-airport services for efficient transit and minimal handling. Door-to-door services for comprehensive logistics solutions and convenience.

On-Board Courier Option:

Expedited delivery services with on-board couriers for urgent shipments. Personal handling and monitoring of high-value or time-sensitive cargo. Reliable and secure transportation with dedicated courier personnel.

Customs Brokerage Management:

Comprehensive customs brokerage services to ensure compliance and smooth clearance. Expertise in navigating complex customs regulations and requirements. Efficient management of documentation and regulatory processes.